Visualization and Measuring Tactile Pressure using Fuji Prescale and FDP 8010 Digital System

Keywords: measuring tactile pressure, pressure profile, 3D pressure visualization, verifying actual pressure with calculated valuesSummary: Tactile pressure is a key value engineers need to measure in order to ensure proper design and manufacturing. Usually the tactile pressure was derived by the bolting force and tactile surface. However, the Fuji Prescale and FDP8010 digital system enable actual measurement and visualization of pressure that is an extremely important step toward improved engineering and manufacturing processes.

Written by Igor Mateski

Importance of Tactile Pressure Measurement

Most of the manufactured goods rely in some form or another on proper tactile pressure. Practically every major industry today uses tactile pressure in some step of the manufacturing process, and therefore all of these industries regularly evaluate tactile pressure:

- Packaging Industry needs pressure measurement to ensure proper sealing of packing materials

- Food Industry uses tactile pressure to ensure proper thermal food processing

- Electronics Manufacturers must track tactile pressure to ensure quality of produced items

- Automotive Industry relies on tactile pressure to ensure proper engine work

- Medicine relies on tactile pressure measurement to ensure prosthetics and ergonomics standards

This is just a short list, but there are literally hundreds of cases in each individual industry where tactile pressure measurement is an integral part of manufacturing and quality assurance.

Usual Pressure Assessment Methods

Project and Quality Assurance Managers rely on indirect procedures of measuring the tactile pressure to get to a working, average value of the tactile pressure throughout the contacting surface.

In mechanical engineering fields like automotive manufacturing, tactile pressure can be calculated by factoring in the resultant bolt tightening force applied to a calculated tactile surface. Although this tactile pressure is a figure defined in the product development phase, going through the arithmetic of establishing the average tactile pressure per surface segment does not help engineers check for manufacturing deviances, plastic deformations of components or even thermal-induced deformations.

In packaging manufacturing measuring the tactile pressure that binds two usually plastic sheets into a packaging container is derived by measuring the tearing/breaking force of the joint by factoring in manufacturing values such as material strength, thickness of the joint edge etc. While this experimental-arithmetic approach does bring better results, the tactile pressure still is a derivative, a function of the manufacturing process and materials.

The Fuji Prescale and FDP 8010 Method

Since most of the experimental and arithmetic methods of establishing the average tactile pressure are approximations and fail to factor in manufacturing imperfections and wear and tear, engineers need a better tactile pressure measuring system.

The only reliable and industry-tested tactile pressure measuring method is to use the Fuji Prescale films. The Fuji Prescale comes in various pressure ranges and there is appropriate pressure range for any use in manufacturing, design or servicing needs.

This site is full of case studies of how the Fuji Prescale film can be used in various industries. However, the Fuji Prescale film can do a lot more than just offering a visual representation of the tactile pressure.

With the FDP 8010 digital system, engineers and technicians have an excellent toolset. Coupled with this digital system, a developed Fuji Prescale film can be scanned and analyzed in a computer. The result of this analysis is a vast amount of detailed data that engineers can use to:

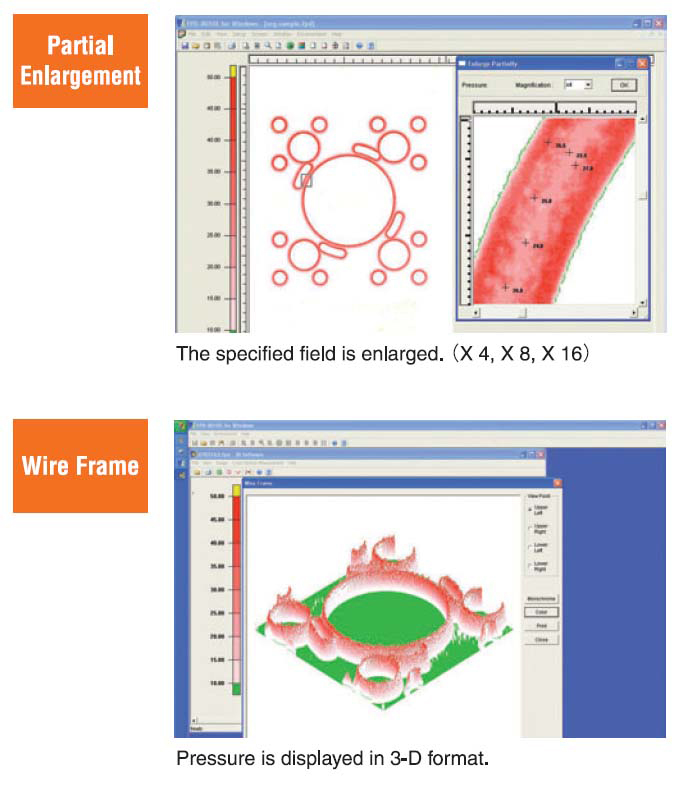

- visualize the tactile pressure on the computer

- zoom in on areas of special interest for visual inspection

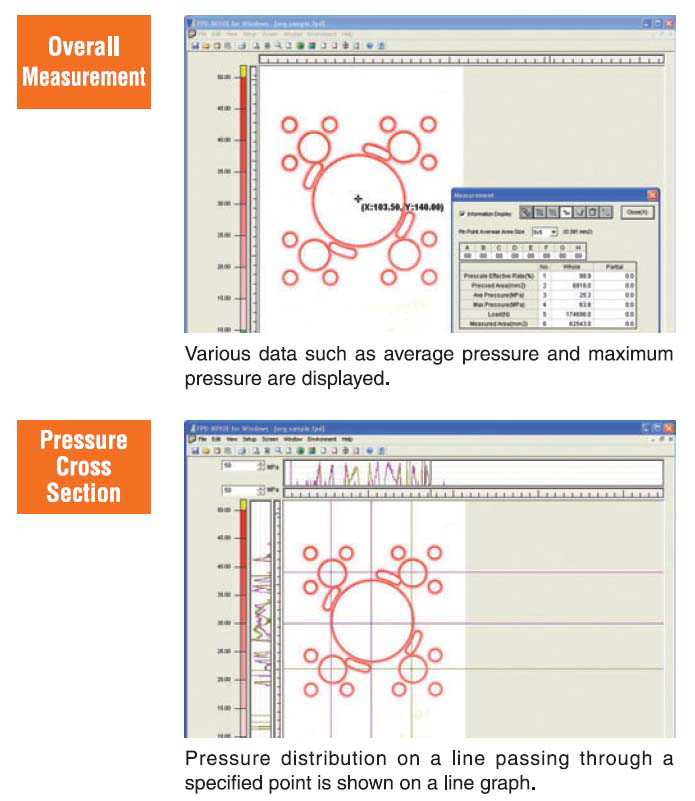

- measuring tactile pressure in every single point on the developed film

- measuring pressure distribution in cross-sections

- export pressure data for further analysis and comparison

- 3D-pressure visualization etc.

Below are actual screenshots of how a developed Fuji Prescale film can be digitized and analyzed on a computer using the FDP 8010 system. The system uses a flatbed scanner to scan the developed Prescale film. The FDP 8010 software offers pressure range selector so that the scanned film can be analyzed properly. This analysis is quite quick and the result of this analysis is a wealth of data that is impossible to get with any other pressure measurement system.

As you can see on the images, the Fuji Prescale and FDP 8010 system is a powerful, versatile and flexible way to measure any tactile pressure in any contacting point. With this system, engineers and technicians have an excellent, fast and affordable pressure measurement and analysis system.