Checking Heat Bar Pressure Balance In Li-Ion Battery Manufacturing

Written by Igor Mateski

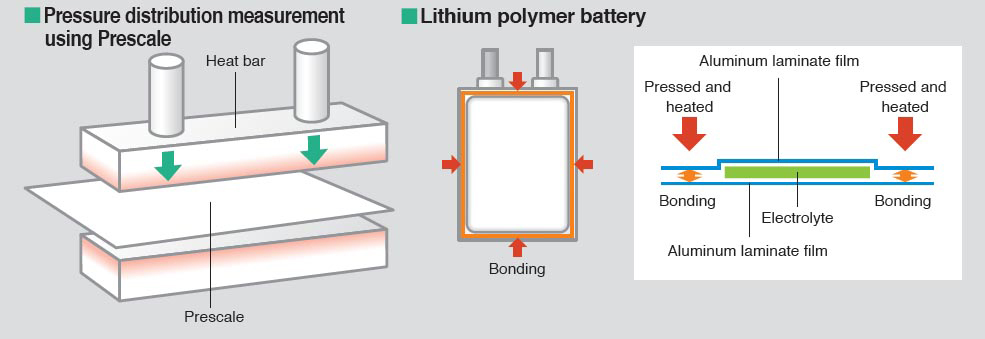

Keywords: heat bar balance, quality assurance, li-ion battery manufacturing, servicing battery sealing equipment, aluminum laminate film, pressure-sealing machine maintenanceSummary: Heat Sealing relies on proper temperature and even pressure distribution along the sealing surface. Any pressure deviances cannot be compensated with increase in sealing temperature, so using Fuji Prescale films to measure pressure distribution is a crucial step in repair and maintenance of pressure-sealing machines.

Importance of Pressure Distribution in Heat-Sealing Processes

Heat sealing as a technical process uses pressure and heat to ensure a seamless joint of two temperature-sensitive surfaces. Depending on the nominal working pressure, the sealing joint can increase in width to create the needed sealing force between two contacting surfaces.

This sealing process needs uniform pressure along the entire width and length of the heat-seal to ensure proper seal quality and reliability. Any pressure discrepancy will result in weak spots along the heat-sealed surface that can cause product failure.

The intimate relationship between heat and pressure in this heat-sealing process is unique. Lack of pressure uniformity cannot be compensated with increase in temperature. This is because of the thermal properties of the sealing material. Increase in temperature can cause air bubbles, wrapping and even tears along the sealed surface.

For a heat seal to properly and reliably do its function, the pressure uniformity is crucial in the heat-sealing process.

While temperature is relatively easy to maintain and check, pressure uniformity is known to be a bigger challenge. But thanks to pressure sensitive tapes and pressure sensitive films like the Fuji Prescale Film, measuring and visualizing tactile pressure is now a straightforward procedure during regular heat-sealing machines maintenance.

Heat-Sealing In Li-Ion Batteries Manufacturing

Proper sealing of the gelatinous electrolyte between two aluminum plates results in high-quality batteries that will be

- Improved ability to hold nominal electrical capacity for longer periods,

- Increase of recharging cycles, i.e increased product lifetime,

- Reliable sealing, i.e safer for the end user.

Battery manufacturers rely on precise pressure distribution along the heat-sealing surface that will hold the gelatinous electrolyte properly sealed between its two aluminum plates. Stronger cell sealing enables manufacturers to make battery stacks with stronger current ratings without risk of battery leaking, overheating or other malfunctions.

Using Fuji Prescale For Quality Assurance

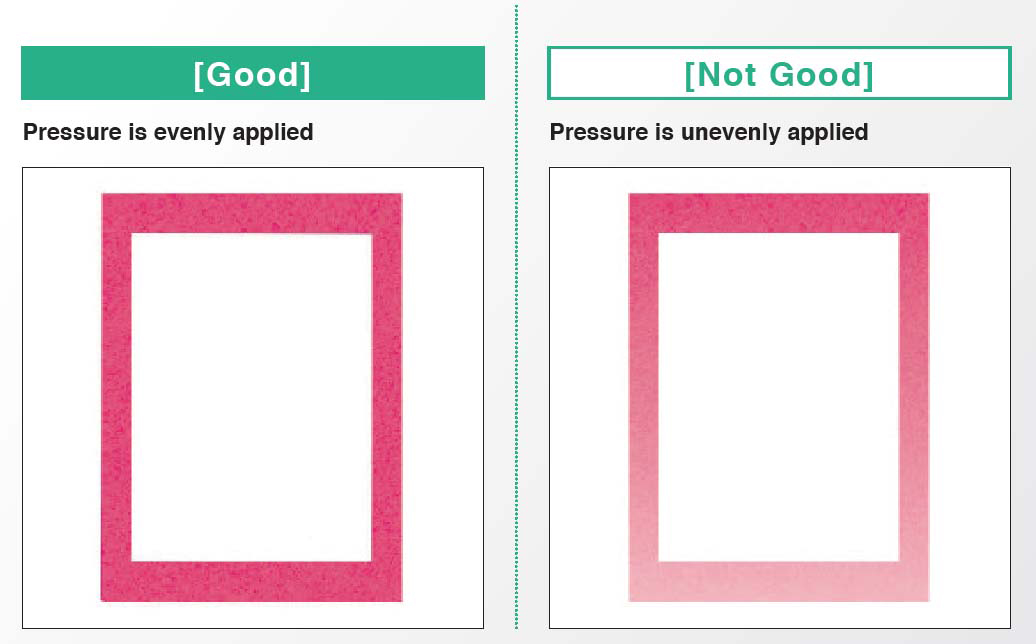

Fuji Prescale enables technicians to quickly and easily measure the tactile pressure exerted by the heat bar and how that pressure is distributed along the length and width of the sealing edges. Pressure uniformity along the width and length of the seal ensures high battery quality, longevity and safety for the end user.

The process of manufacturing and quality assurance is also improved as technicians can quiclky intervene and do any needed adjustments to ensure uniform pressure distribution and therefore ensure proper heat-sealing process of the li-ion battery.

Below is a sample usage of the Fuji Prescale Film in Lithium-Ion battery manufacturing.

There are two ways that Fuji Prescale can help:

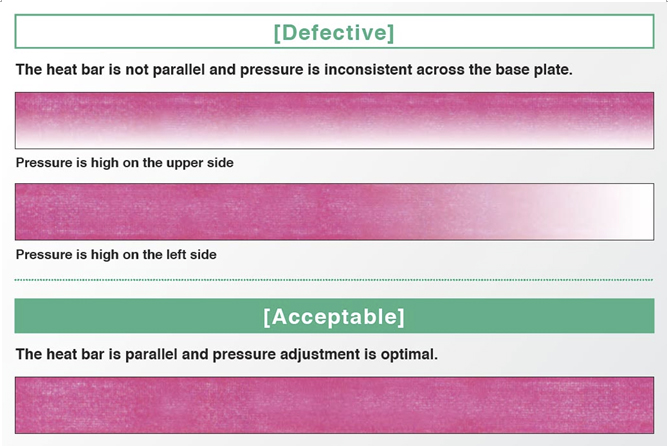

- discover pressure issues with the base plate-heat bar alignment

- reveal pressure issues along the width and length of the heat seal edges

In the image above, the rectangular shaped heat bar is not properly aligned with the base plate and the pressure it exerts onto the aluminum foils is not uniform. At one end the pressure is lower than nominal (image on the right), and in this case the heat seal will not be strong enough to cope with the battery's working conditions during its lifetime.

In the image below, the Fuji Prescale film reveals a different, and more difficult pressure problem to find. In this case, the actual surface of the heat bar is not flat probably because of wear and tear. This uneven contacting surface of the heat bar inevitably causes pressure issues, where the tactile pressure is uneven along the width and length of the heating surface. This in turn causes heat seal issues that are difficult to discover, but will quite negatively impact the battery's longevity and safety.

In order to avoid these manufacturing problems, using the Fuji Prescale film during regular maintenance inspections is a must.

Such reliable maintenance and repair will result in:

- increase in quality of the products

- increase in reliability of the batteries

- increase in battery manufacturing

Thanks to the pressure characteristics of the Fuji Prescale film, repair and maintenance technicians can quickly and easily evaluate the pressure profile of the heat-sealing machines and ensure fast repair interventions.