Using Fuji Prescale To Align Brass and Steel Samples in Metalic Microparts Extrusion Manufacturing

Keywords: Kolsky bar, brass microextrusion, friction temperature, pressure map, tactile pressure measurement, fuji prescale

Summary: Using the Fuji Prescale film helped engineers properly align brass and steel plates and come to proper conclusions about the source of extruded micropart deformations.

Source: Horacio D. Espinosa, Study of the Size Effects and Friction Conditions in Microextrusion-Part II: Size Effect in Dynamic Friction for Brass-Steel Pairs, Journal of Manufacturing Science and Engineering, August 2007, Vol. 129.

Written by Igor Mateski

The Challenge of Manufacturing Metallic Microparts

With increased demand for reducing dimensions in products engineers are facing a growing demand for mechanical elements that have at least two dimensions on the scale of 1mm. These devices, also known as metalic microparts, play important roles in electronics, medical, mechanical devices.

One of the most widely used manufacturing process for microparts is microextrusion. Microextrusion allows for high-scale manufacturing where the time per unit produced is very short, and consequently, microparts can be cheaper. However, microextrusion has its technical limitations and challenges:

- Unpredictable deformation because of small dimensions

- Heat spikes caused by friction during extrusion

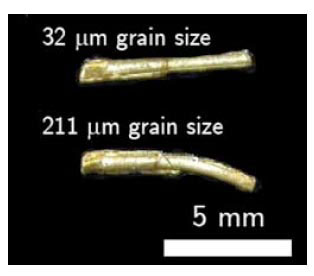

The image below shows how these microelements deform. There are noticeable patterns in the way these products are deformed:

To ensure proper manufacturing processes and avoid deformation of microparts, various teams of engineers set off to determine why deformations occur.

What Causes Deformation in Brass Microparts Extrusion

The research teams did experiments to see how friction heat can be reduced. As the tools are usually made of steel and brass is the material of choice for microparts extrusion, these experiments were done to evaluate the interaction between steel and brass and why microparts twist and bend unpredictably.

The research started off evaluating the effects of contact pressure, speed of extrusion and friction coefficients and resulted in a series of conclusions:

An important conclusion that can be drawn from the fact that the friction coefficients do not significantly vary with grain size or contact area is that the curving tendency of the submillimeter sized pins is related to the material response... The curving tendency of submillimeter-sized pins is not related to the friction but to the material response.

The Benefits of Using Fuji Prescale in Microparts Manufacturing

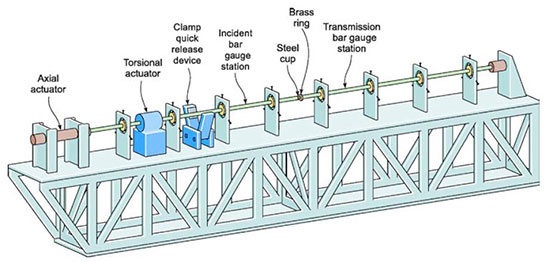

Espinoza et.al. resorted to the torsion Kolsky bar to evaluate how pressure, coefficient of friction and dimensions affect heat and deformations. Below is a schematic representation of how the Kolsky bar was used to test the interaction between a brass and steel plate. Engineers used precise readouts and several different materials, pressure and torsion settings to evaluate what variables affect microelement deformations.

The Kolsky bar rig basically enabled engineers create various scenarios with different settings for torsion, tactile pressure and surface area. This experiment series helped engineers get computable values for friction coefficients that later helped in getting a working solution of which variable is responsible for microelement deformations.

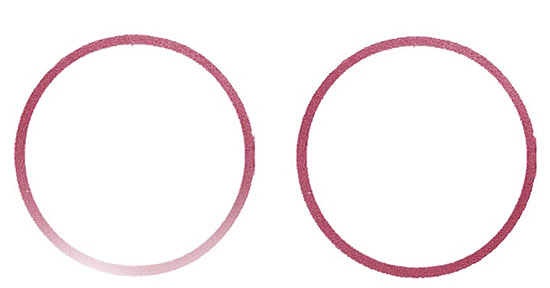

As friction coefficients may vary if plate alignment is even slightly off, engineers used Fuji Prescale films to map the tactile pressure and ensure proper pressure distribution throughout the contact surface between the brass and steel plates. Before any tests could be done, engineers had to ensure proper planar alignment:

The image above shows two Fuji Prescale pressure maps. The detail on the left is from a case when the brass and steel plates were not properly aligned. This misalignment would have significant effect on the results. So to ensure good alignment the two plates are machined on the spot for improved alignment.

The detail on the right is a pressure map of two perfectly aligned plates. With this result, engineers can continue on with the experiments using various contact pressure and torque values.