Using Fuji Prescale Film to Verify Heat Seal Integrity in Medical and Food Industries

Keywords: heat-sealed packaging verification, testing pharmaceutical heat sealing process, verifying heat seal integrity in food manufacturing, servicing heat sealing machines.Summary: Heat-sealed packaging is crucial to product longevity and quality, especially in medical and pharmaceutical industries. In clean rooms, the ideal way to verify quality of heat-sealing process without contaminating the area with dust particles is using the Fuji Prescale film to verify sealing integrity.

Written by Igor Mateski

The Importance of Heat Sealing

Products that need to be sealed off in an air-tight container rely on such high quality packaging in order to meet industry standards for product safety, product longevity and product usability without adding chemical preservatives.

This is especially important in medical industries such as pharmaceuticals (manufacturing of medicine) and medical plastics manufacturing (eg. ensuring air-tight seal for germ-free syringes).

Food production facilities also rely on heat-sealing packaging for various products ranging from bread to frozen meat. In this case, the integrity of the seal directly influences shelf life of the product, and consequently affects the profitability of the entire chain from production to consumption.

Problems in Heat Sealing Process

Heat sealing relies on a fine balance between temperature of the sealing jaws, pressure excreted to the packaging foil, and time of exposure. These three metrics are key to establishing a reliable heat-seal each and every time.

However, as medical and food industry relies on large quantity of daily manufacturing, problems are bound to happen. There are two testing procedures of the heat seal integrity:

- measuring time of exposure and temperature of sealing jaws

- peel strength testing (JIS Z0238)

The time/temperature procedure relies on a finely balanced ratio of time and temperature to ensure heat accumulation to just the right extent so that the two surfaces are hot enough to bind, but not too hot as to form bulging and creating air pockets. In a sense, this requires a perfect chemical and mechanical properties of the foil on its entire length and width, which is sometimes not the case.

The second test can only be applied to sample items, and from a statistical perspective, it is not perfect because of the imperfections of the packaging materials.

In this regard, although manufacturers can establish the pre-defined quality standards, it is almost impossible to make sure that the heat seal integrity is unchanged along the width and length of the sealed area.

Fuji Prescale Benefits in Verifying Heat Sealing Process

In a contact-sensitive sealing process, one of the most important variables is the contacting pressure between the sealing jaws. Even if the timing and temperature are dynamically adjusted to compensate any chemical and mechanical inconsistencies of the packaging materials, the best way to make sure sealing is done properly is to measure the tactile pressure between the sealing jaws.

This is an especially useful diagnostics tool in the medical/pharmaceutical industries that require clean rooms with specified particle count per cubic meter of air. In such facilities performing any measurements that require extra tools is simply unacceptable and testing sealing machines can mean shutting down production.

With Fuji Prescale, the Fuji Prescale Super-Low Pressure tactile film can be applied between the sealing jaws for fast, clean and efficient verification of the seal integrity.

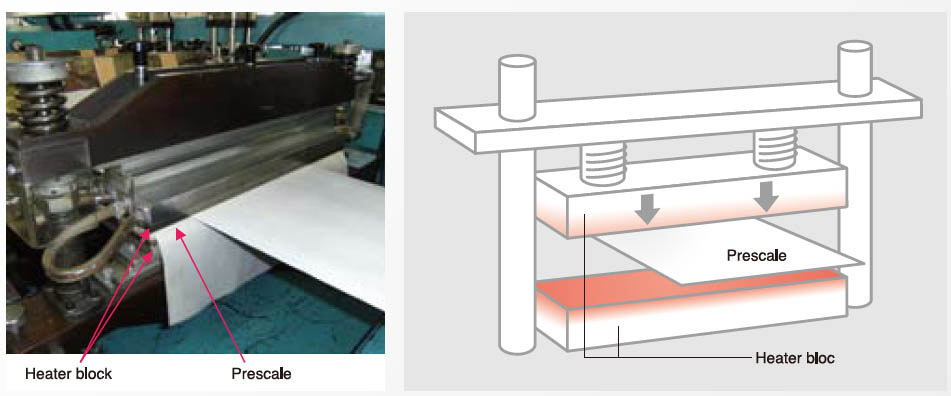

As it is illustrated on the images above, the Fuji Prescale film is placed between two sealing jaws, and they are then pressed together with the nominal pressure (heating not applied). The developed film will show how the two plates are aligned one relative to the other.

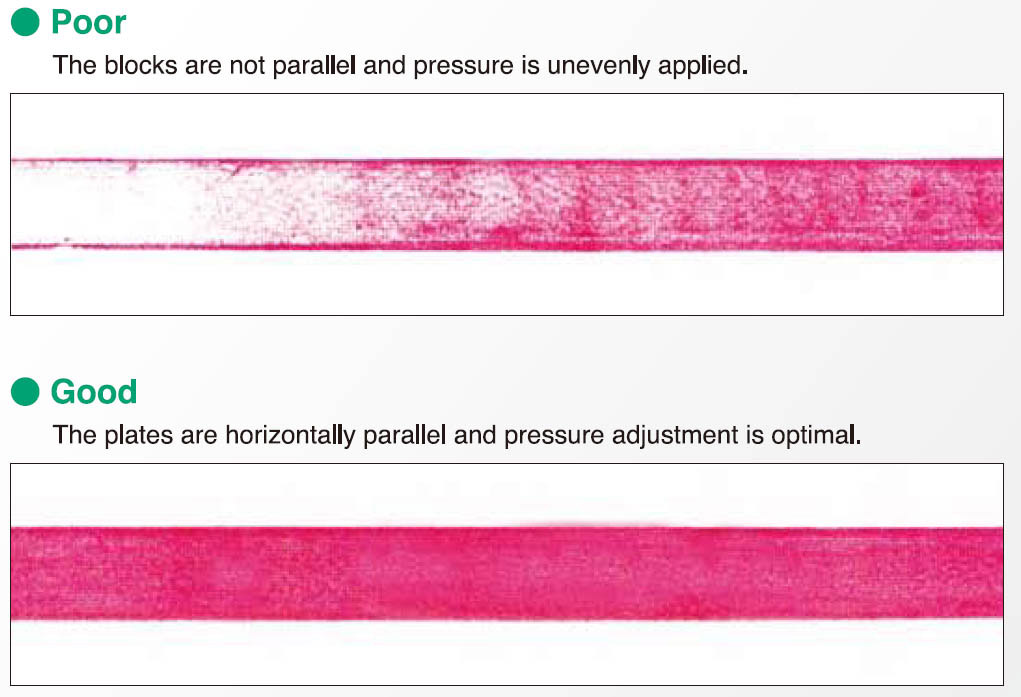

The image above shows actual developed films from a heat sealing machine. The first image is from a machine with defective sealing surface. The defect is subtle. The apparent lack of contacting pressure at the left half of the contacting surface is misleading, and this is not a case of reduced pressure exerted onto the heating jaws. The two border lines clearly point that pressure is being applied but the actual contacting surface is deformed, i.e bulged inward. This usually happens with ceramic heating elements. If it was a metal heating element the bulging would be outward.

Without a Fuji Prescale pressure sensitive film, this diagnosis would be impossible to establish. But thanks to the fine pressure sensitivity, repair technicians can pinpoint the problem and solve it quickly and efficiently, eliminating any guesswork, any trial-and-error, and ultimately, bringing the manufacturing down-time to a minimum.