Using Fuji Prescale Film to Map Tactile Pressure in Super Seal Gaskets Design

Written by Igor Mateski

Keywords: fuji prescale film, map tactile pressure, pre-tension force sealing, measure sealing with fuji prescale, metal gasket design

Summary: Asbestos gaskets are hazardous and are being replaced with metal ringed gaskets that rely on metal deformation to provide sealing. Using the Fuji Prescale film, engineers can directly measure the gasket sealing properties for nominal bolt tightening forces.

The Mechanics of Metal Gaskets Sealing Action

Asbestos gaskets proved to be quite reliable, but as Asbestos is a hazardous material it is being banned throughout the world and engineers are pressed to use other ways to ensure proper sealing of bolted joints.

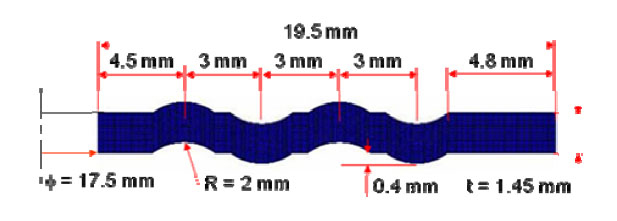

A Japanese team did a research reviewing a new, metal gasket, the Super Seal gasket. This new metal gasket relies on circumferential annular lips to establish a proper sealing pressure:

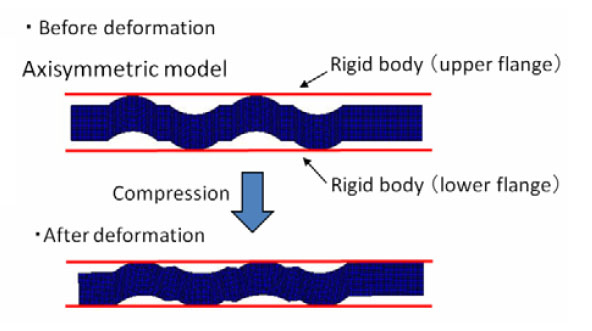

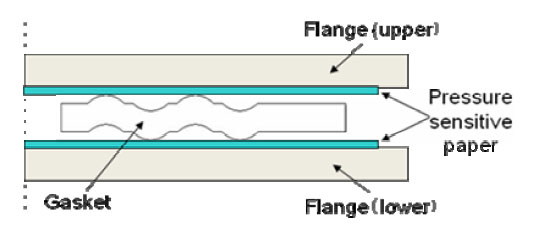

These "lips" work as ridges that get in contact with the opposing metal plates and the bolt-tightening action causes deformation of the lips so that the ridge forms a tight strong contact ensuring proper sealing, as illustrated below:

The sealing action is ensured by two concentric ridges on both sides of the gasket that form tight bond with the rigid bodies that provide the clamping pressure applied by the tightened bolts.

An engineering challenge here is to verify if this clamping force is strong enough to provide the needed tactile surface and tactile pressure in order to ensure proper sealing for the given nominal bolt tightening force as well as the working pressure of the fluid.

FEA Mapping Tactile Pressure Created by Nominally Tightened Bolts

When designing gasket bolted joints we rely on bolt tightening force and number of bolts to calculate tactile pressure that must be high enough to ensure sealing action depending on the gasket used. However, friction and imperfections result in inaccurate tactile pressure that is expected according to calculations.

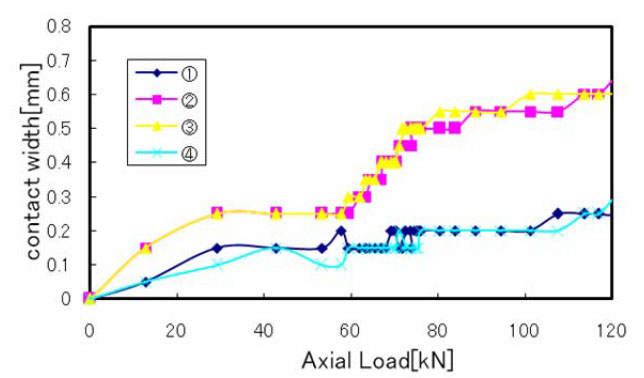

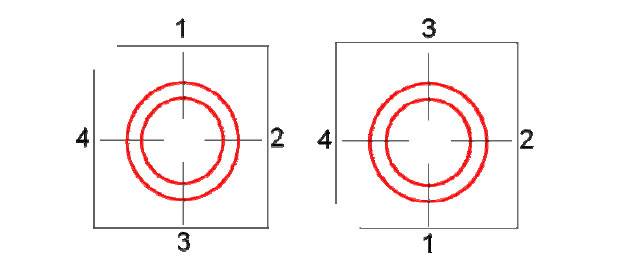

With this new super seal metal gasket, the sealing action is achieved by deformation of the concentric ridges which further complicates the issue of how much pressure is enough for the given application. The Japanese research team measured pressure in four points along the concentric ridges and also measured the width of the contact surface. Below is a chart illustrating the different width in points 1-4 for any given tactile pressure:

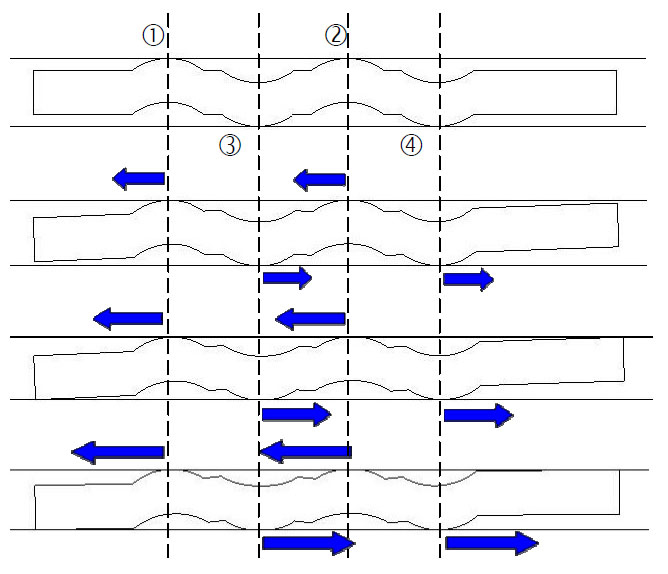

Below is a chart of how the contacting points were selected. The top surface pressure and tactile width was measured in two points (points 1 and 2), while points 3 and 4 measured pressure and width on the bottom side of the gasket.

The Phenomena of position change on the convex contact at load of 0,40, 80 and 120 kN

The FEA model showed that there is better contact surface and tactile pressure on the inner ridges, i.e points 2 and 3, while 1 and 4 followed the same curve of load-contact curve (see previous image).

Benefits of Fuji Prescale vs. FEA Pressure Profiles

Visualizing the actual tactile profile is crucial in order to know the sealing capacity. Tactile pressure FEA profile is different due to complex metal gasket sealing deformations and is difficult to factor in all variables for the FEA model. The Japanese team used the Fuji Prescale film to measure the actual axial force and tactile surface of this metal gasket. When comparing the FEA values with the actual Fuji Prescale values researchers discovered inacuracies in the FEA model that were caused by several factors:

- the axial load factor in the FEA model was not accurate due to bolt friction during tightening

- clamping order also affected overall clamping force exerted onto the sealing ridges

- complex deformations of the ridges were impossible to predict and factor in

Measurement procedure using pressure sensitive paper

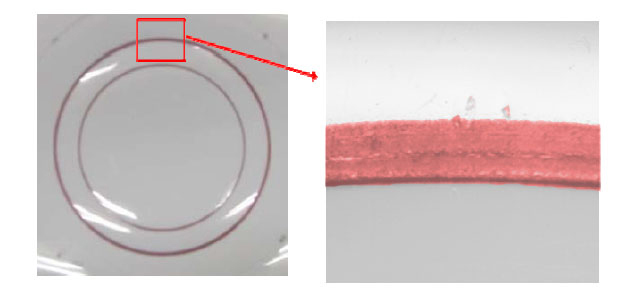

The two developed Fuji Prescale films showed the exact width of the tactile surface created between the ridges and plates. After digitizing the readouts engineers can precisely measure the tactile pressure at each point along the contact surface and verify if the gasket is providing a proper sealing of the bolted joint.

Below are screenshots of the developed Fuji Prescale films:

The contact width measurement on the upper and lower of pressure sensitive paper

The detailed view below is from a measurement done under a nominal axial load of 120kN:

The red patches appeared on the pressure sensitive paper at 120 kN load