Using Fuji Prescale As Comparative Measurement of Thermal Conductivity Between Aluminum Plates

Keywords: passive heat sink design, thermal conductivity, tactile pressureSummary: Thermal conductivity between two metal bodies increases as the tactile surface and pressure increases between the two metal plates. Thermal Engineers can resort to Fuji Prescale films as co-relational method of measuring thermal conductivity cheaply and efficiently.

Written by Igor Mateski

The Issue of Thermal Conductivity

Thermal conductivity between two metal plates as a physical and engineering concept revolves around maximizing the heat transfer between two bodies at different thermal levels. The issue of thermal conductivity is especially important in the electronics industry, regardless if it's an issue of keeping the computer CPU cool, or it's keeping a nominal working temperature in a satellite. Cooling of electronics devices such as microchips, high-capacity hard drives etc. is a huge problem especially nowadays as devices tend to get even smaller and more power efficient. Power-saving in turn makes active cooling systems undesirable, so heat transfer and dissipation must be done passively.

Thermal Conductivity Methods

As power consumption, noise and vibration influence on the user-friendliness and price of the device, engineers try to find ways of establishing solid thermal conductivity by using passive heat sinks. Usually, passive heat sinks have a flat contacting surface which is the area of thermal conductivity through which the cooled device releases its heat onto the cooler. To achieve high thermal conductivity engineers have used thermal paste, usually silicon-based solvent that is applied in small amounts to ensure even contact between the hot component and its passive heatsink.

Fuji Prescale and Thermal Conductivity

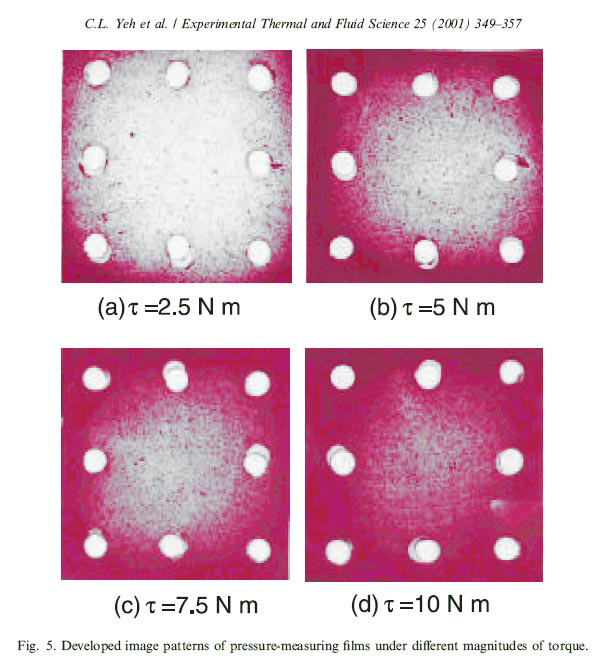

Research shows that tactile pressure directly influences heat transfer capacity of the adjacent metal surfaces. In fact, a study showed that when two aluminum plates were bolted together with evenly spaced out 8 bolts, the thermal conductivity in bare-metal contact was higher than when using a silicon-based thermal paste. The image below is a screenshot of developed Fuji Prescale films that measure tactile pressure between two aluminum plates bolded together with 8 bolts.

The research team discovered that there was a direct correlation between the bolt-tightening force and the coupling thermal conductivity. Researchers concluded that the best thermal conductivity is reached when the contacting surfaces have high surface machining quality and high bolting force.

Such high surface flatness and high tactile pressure ensures maximum contacting area over which heat is being transferred from the heating element onto the heatsink, better than when using lower surface quality and pressure with a thermal conducting silicon-based paste.

Based on this conclusion, that thermal conductivity is directly affected by tactile pressure and surface area, engineers can leverage the Fuji Prescale film readouts as a visual representation of how much heat transfer will occur.

Thanks to this research finding, engineers now have a very simple, fast and most importantly cheap way of measuring heat transfer where the developed Fuji Prescale film can even work as a substitute for thermal imaging cameras.