How to measure tactile pressure: Easy and Precise Pressure Profile Visualization

Keywords: Fuji Prescale Film, Pressure Sensitive Film, 3D pressure visualization Summary: Determining the actual pressure distribution vs. the calculated pressure values helps engineers and repair technicians improve the engineering and repair process using Fuji Prescale films to visualize the pressure distribution between two contacting surfaces. Written by Igor MateskiWhy measuring actual tactile pressure is important

Measuring the exact tactile pressure between two surfaces is very important for design checkups, as well as diagnostics and repair purposes. When a design leaves the drawing board and is sent off to prototyping, we already know the needed bolts tightening force, the contact surface size, and theoretically, we also know the tactile pressure.

However, calculated forces and measured forces sometimes do not match completely because of various reasons:- Contact surface quality is not as required

- The bolts are not transferring pressure equally

- Contact surface varies from specified size

There are numerous other reasons why a calculated tactile pressure usually is not equal to the actual pressure in any given location on the contact surface. Pressure distribution discrepancies can mean the difference between a working product and spending another month at the drawing board.

Tactile Pressure Profile

With products that have high operational pressure, the exact tactile pressure between different parts is extremely important:- Pressure between contacting surfaces on high-pressure valves

- Pressure profile between cylinder head and block of internal combustion engines

- Pressure distribution on fan-axis joints in high-pressure pumps

In such cases, the ideal option is to have a way of measuring not only pressures in different points, but actually having a visual representation of pressure distribution throughout the contacting surface. With this pressure profile engineers can easily see ways to improve the design, or evade a fatal design flaw. In repair shops, measuring the tactile pressure can help repair technicians establish the level of defect of contacting parts that can help in treating the root cause of the failure instead of going down the symptoms-healing path.

The Most Effective Tactile Pressure Measurement: Fuji Prescale Film

The Fuji Prescale Film is an extremely thin (200μm) and stable tactile measurement film that can help you measure tactile pressure in various scenarios:- Eight types of Prescale available to fulfill your varying pressure range: 7.25 PSI to 43,500 PSI(0.05 to 300 MPa)

- Flexible and easy to apply to non-flat contacting surfaces

- Immediate pressure profile insight thanks to color capsules technology

Measuring a tactile pressure with Fuji Prescale Film:

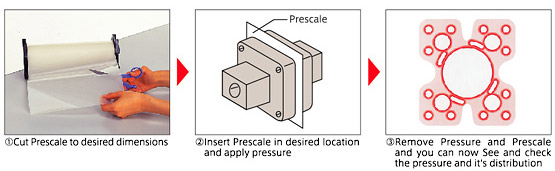

Measuring the tactile pressure between two contacting surfaces is very easy with Fuji Prescale Film. All you need to do is cut the Fuji Prescale Film to the needed dimensions, insert it between the contacting surfaces, and apply the nominal pressure. The applied pressure activates the color capsules, and you can quickly and easily see the pressure distribution once you remove the Prescale film.

In this way, you can quickly establish the pressure profile, and, if you scan the Prescale with the Fuji Pressure Distribution Mapping System, you can even read out pressures at specific points and even generate a 3D pressure map.