Quality Control In Photovoltaic Manufacturing With Fuji Prescale

Keywords: photovoltaic manufacturing, quality control, vacuum lamination, tactile pressure distribution measurement, fuji prescale quality assuranceSummary: Laminated Photovoltaic elements manufacturing relies on vacuum lamination that ensures even tactile pressure distribution. Any pressure distribution can cause wrinkling and damage to the laminates and result in faulty photovoltaic elements. Using Fuji Prescale to directly measure pressure distribution is the only direct method for manufacturing quality control.

Written by Igor Mateski

Challenges in Laminated Photovoltaics Manufacturing

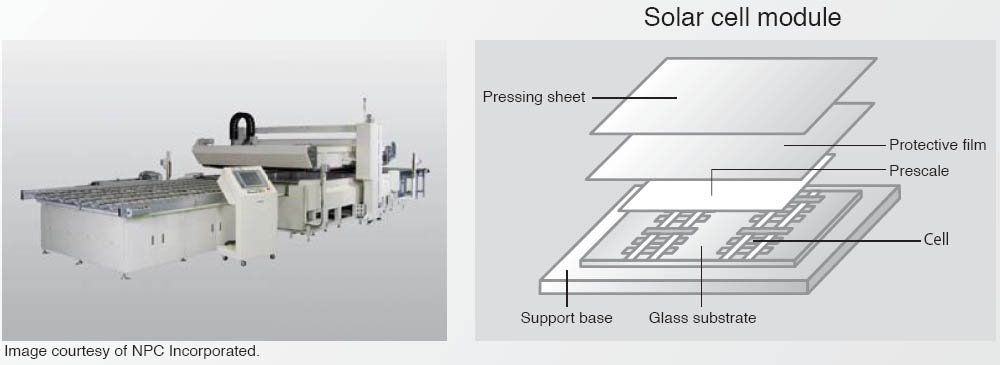

Photovoltaic elements are laminated products that need even pressure distribution for a proper lamination and maximum lifetime. The lamination components are basically the photovoltaic elements that need to be cemented onto a glass substrate and this lamination process must be flawless every time.

As the photovoltaic elements grow larger, and demand grows for thinner/lighter substrate, pressure distribution increasingly becomes an issue. Since the photovoltaics are fragile, as is the glass, increasing the nominal pressure (i.e vacuum) the lamination press achieves is not an option because larger tactile pressure can cause breaking of the elements.

On the other hand, achieving even tactile pressure on larger surfaces under a relatively low vacuum is a big issue because pressure variations can cause wrinkling of the protective film which reduces the voltaic output of solar cells.

The Importance of Quality Control

Quality Control technicians have had the ability to measure tactile pressure based on the vacuum level but such indirect measurement is not enough for a reliable manufacturing process. This is why quality control is done on manufactured solar cells. So technicians need a batch of solar cells they can then test and detect any defect patterns so that a clear diagnosis can be established. Such retrospective approach to Quality Control is costly, time consuming and an iterative process.

Solar cells must produce a certain voltaic output. As voltaic output is directly related to the lamination quality, manufacturers must ensure high yield as well as high quality. The problem is that with a retrospective quality control of photovoltaic manufacturing, to a degree, yield is inversely proportional to quality.

How Fuji Prescale Helps in Photovoltaic Quality Control

The relation between production yield and production quality can be fixed if quality control technicians have a way of directly measuring the tactile pressure between the laminated stacks. With such a method, quality control could be done on-the-fly, without costly test batches and with zero material loss.

The Fuji Prescale Film is the only way to quickly, accurately and cheaply measure the laminating tactile pressure. Technicians can get a visual representation of tactile pressure and quickly establish a precise diagnosis of the lamination process.

Below is an illustration of how technicians can use the Fuji Prescale in visualizing the tactile pressure between laminates.

The image shows how easy it is to use the Fuji Prescale film:

- Place the Fuji Prescale film between the glass substrate and protective film

- Place the Pressing sheet on top and apply the nominal vacuum

- Take out the developed Fuji film for a direct readout

Thanks to this direct pressure readout technicians can easily establish a proper diagnosis and work on a solution.

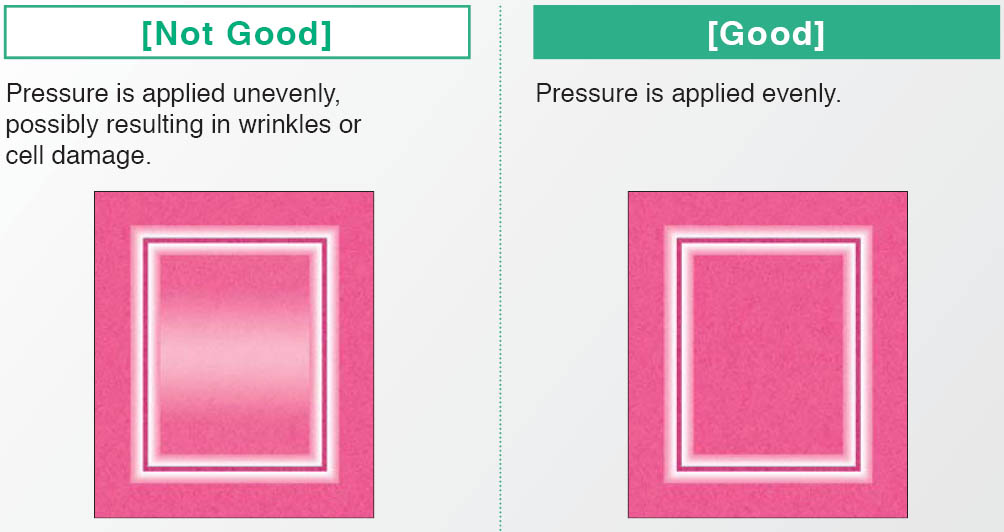

Below is a sample image of developed Fuji Prescale films:

The image on the left reveals a defective lamination process. Notice how there is a pressure disbalance in the closed up section. This uneven tactile pressure can cause wrinkling of the protective layer, or can damage the photovoltaic elements. In both cases, the end result of this manufacturing process is a solar cell that will not produce the nominal voltage.

Thanks to the direct pressure readout technicians can quickly adjust the manufacturing equipment and establish an even tactile pressure distribution, as is shown on the image to the right. Notice that there is obvious improvement of the pressure distribution and there is no discoloration (pressure variance) on the entire laminating surface.

With Fuji Prescale, technicians can save a lot of time in diagnostics, save a lot of materials by avoiding faulty products and save time in regular maintenance and quality control.