Using Fuji Prescale as Quality Assurance in Fuel Cell Manufacturing

Keywords: fuel cell stack pressure, fuel cell quality assurance, improve fuel cell efficiency Summary: Fuel cell manufacturing relies on even tactile pressure between individual cells and electrolyte membranes. With Fuji Prescale films, manufacturers finally have a direct way to measure tactile pressure and ensure high production quality. Written by Igor MateskiImportance of Tactile Pressure in Fuel Cell Manufacturing

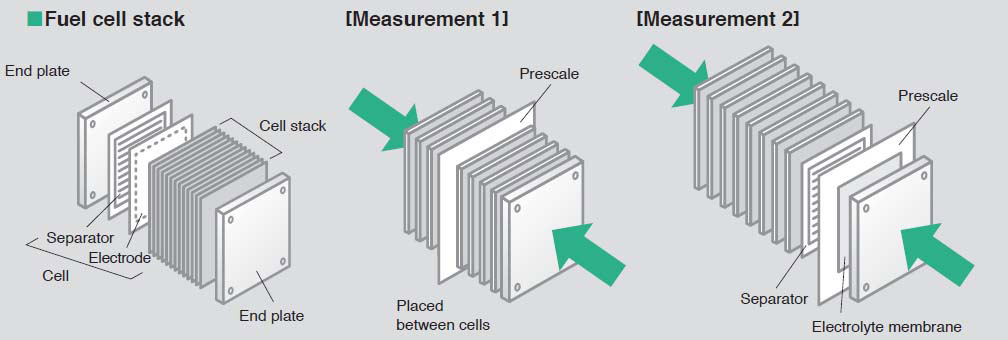

Fuel cells are individual cells stacked in a single unit to match the required voltage and amperage. Depending on the power requirements, fuel cells manufacturers can stack more cells and combine cell assemblies.

Because of dimension and temperature limitations, fuel cells need to be packed in as small a dimension as possible, without the threat of overheating. This puts a big demand on the manufacturing process that needs to ensure even surface pressure between individual cells, every single time.

If the tactile pressure is not within specified values (not too low, and not too high), the fuel cell assembly can suffer from:

- Increased contact resistance

- Lower power generation

- Cells leaks

- Sealing material deteriortion

Because of this sensitivity to pressure, the manufacturing process relies on putting the exact torque on all tightening bolts so that the pressure is evenly distributed on the entire cell surface. But with materials change or human error, the need to test this pressure as Quality Assurance is still a required step. Otherwise, entire batches of fuel cells may end up as defective items sold to end users.

Fuel Cell Quality Assurance with Fuji Prescale

Although there is a way to know the pressure at every area around the tightening bolts, there is no way to know the pressure value on every contacting point on the cell surface. This is why manufacturers of fuel cells need to use the Fuji Prescale film and test the pressure between individual cells, and between the cells and electrolyte membrane.

In the image above is an illustration of how to measure the tactile pressure between two cells (Measurement 1), and the surface pressure applied on the electrolyte membrane (Measurement 2).

In both cases, the fuel stack needs to be dissasembled so that the fuji prescale film can be inserted at the appropriate place. Then the assembly is put back together and the tightening bolts are loaded with the nominal torque. After the nominal pressure load, the developed fuji prescale films can be inspected, as is shown on the image below:

The developed fuji prescale film to the left is from a properly loaded fuel stack. Here the tactile pressure is constant throughout the contacting surface and the nominal torque creates the needed pressure. In the image to the right however, the fuel cell assembly is not properly loaded and the torque values of the bolts needs to be adjusted, or the end plates may be deffective.

Thanks to the ability of Fuji Prescale to adapt to any surface and pressures, fuel cell manufacturers now have the perfect tool to measure tactile pressure between individual cells and between cells and electrolyte membranes. This ensures standard quality of all manufactured items, and the Quality Assurance team can also spot any irregularities early on in the manufacturing.

This saves time, raw materials, and it also preserves the good name of the manufacturers.