Manufacturing Better Touch Panels With Fuji Prescale

Keywords: touch panel manufacturing, lcd manufacturing, capacitive touch panel sensitivity, touch panel precision Summary: Small form factor devices like smartphones and GPS devices rely on high quality touch screens, touch sensitivity and touch precision. With Fuji Prescale, the manufacturing can be greatly improved while reducing R&D and servicing costs. Written by Igor MateskiTouch Screens Manufacturing Challenges

Binding LCD displays with a resistive or capacitive touch sensitivity is a very challenging process. This challenge is even greater with the multi-touch sensitivity of small devices like smartphones, GPS devices and PDAs.

Manufacturing small multi-touch sensitive LCDs requires a controlled environment (dust, temperature, humidity) but it also requires precision machinery so that the adhesion of the touch-sensitive layers and protective glass get an even and clean contact with the LCD panel.

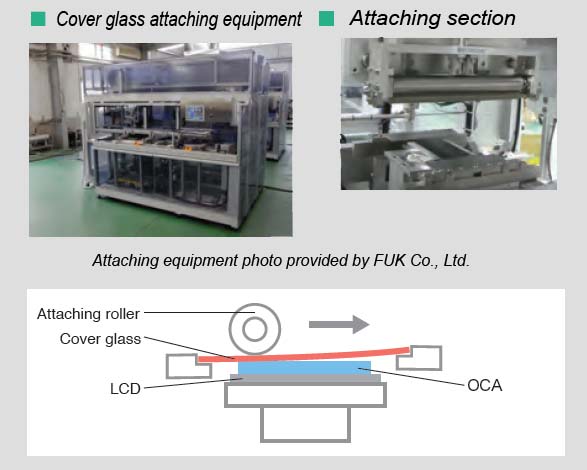

The image above gives a schematic overview of how the binding of the protective layer, touch-sensitive layer and the LCD get bound in a single unit. This process requires precise pressure distribution so that there are no air pockets trapped at the contacting surfaces. If air or dust particles do get trapped, the touch-sensitivity will be uneven, which can cause some areas to be less sensitive, while other areas can be over-sensitive.

Touch panel manufacturers usually rely on taking samples from manufacturing batches and test the panels for touch sensitivity and touch precision. This method is backward-looking as defects and imperfections only get discovered after the fact. Such Quality Assurance costs manufacturers various losses:

- Loss of production time due to defect removal

- Loss of raw materials due to defective batches of products

- Loss of repair time due to reverse-engineering procedure of repairs

In order to minimize these losses, manufacturers can either increase the amount of testing of produced goods, or opt for using the Fuji Prescale film to forward-looking defect removal.

Fuji Prescale as Quality Assurance of Touch Screens

One of the best ways of ensuring high manufacturing quality of touch-sensitive LCDs is to use the Fuji Prescale LLLW (Ultra-Super Low Pressure) film regularly.

The image below shows how the Fuji Prescale should be used: place it between the roller and adsorption table. This will read out the pressure distribution along the entire length and width of the contacting surface and will help engineers and maintenance technicians to discover any pressure variances.

If the developed Fuji Prescale film looks similar to the image to the left, the manufacturing process is flawed. The image above shows that the pressure distribution between the roller and plate are not even, which in turn creates pressure ridges that can damage the pressure-sensitive components or result in an area that is overly-sensitive to touch-pressure. On the other hand, the areas where the adhesion pressure is smaller, there is a chance of trapping air bubbles which will cause the area to not be pressure-sensitive.

Repair technicians can easily establish the proper diagnosis: the rotation axis of the roller is not properly aligned with the adsorption plate. There is also a possibility of the roller surface to have suffered damage so the roller may need replacing too.

After servicing the machine, the developed Fuji Prescale film should be evenly pressure-loaded, like it is on the image to the right. In this case it is obvious that the pressure is well-distributed along the length and width of the contacting surface, which means that both the roller axis and surface are up to the required specifications.

Benefits of Using Fuji Prescale in Touch Screen Manufacturing

Using the Fuji Prescale LLLW grade film can greatly improve productivity and reliability of touch screens:

Benefits of Using Fuji Prescale in Semiconductor Production

Using the Fuji Prescale LLLW grade film can greatly improve productivity and reliability of touch screens:

- Fuji Prescale helps in easy and quick defect discovery

- Fuji Prescale is a great diagnostics tool

- The pressure sensitive film is an inexpensive way of measuring and ensuring quality

- Manufacturers can service the equipment long before there are defective products

Thanks to the Fuji Prescale LLLW film, touch panel manufacturers can greatly increase their output, product quality, while reducing loss of materials due to defective manufacturing.