Fuji Prescale Film as a Gasket Sealing Tester

Keywords: gasket sealing, head-body pressure mapping, sealing force testing Summary: Internal combustion engines rely on uniform pressure distribution at the body-head junction to ensure proper combustion and cooling. Due to manufacturing errors and engine operation outside the optimal conditions, heat-induced deformations can cause loss of sealing properties of the gasket sealer. Fuji Prescale films can assist repair technicians to discover the location and amount of deformation, and repair the defect. Written by Igor MateskiHeat-induced defects in internal combustion engines

Internal combustion engines are high-pressure and high-temperature engines that also generate a lot of vibration. These working conditions accompany the engine for hours on end, day in and day out, for years. Heat, pressure, vibration and time are all working together toward breaking down the engine.

Some times, users have the engine running outside of its optimal parameters:

- Low engine oil level or old oil that loses its lubricating capacity

- Low coolant level that affects the heat dispersion capacity

- High-revolution engine exploitation for long periods

Such engine operation adds up and the engine heats up more than the material can bare within it's elastic deformations curve. Once the elastic deformation loads exceed, the material goes into plastic deformations and the engine breaks down.

Repairing gasket sealing defects the usual way

Overheating defects are very common and among the primary manifestations of engine failure are:

- Mixing coolant liquid with the engine oil

- Loss of compression in the cylinders (common in Diesel engines)

- Complete engine failure due to fusing of the piston and the cylinder

The usual way of repairing such engine failures is to take apart the engine, replace the defective parts and cut down the engine head for several hundreds mils off the contacting surface with the engine body.

This kind of engine head repair requires time and it usually costs more. In some instances, the plastic deformation is greater than anticipated so the repaired head will need to be taken of the engine and re-cut again. This trial-and-error approach is tedious, imprecise and quite slow.

Using Fuji Prescale as the optimal repair method

Since repair technicians do not know the location and extent of the plastic deformation of the head, they cannot know what repair extent is needed so that the gasket sealer can do its sealing job properly.

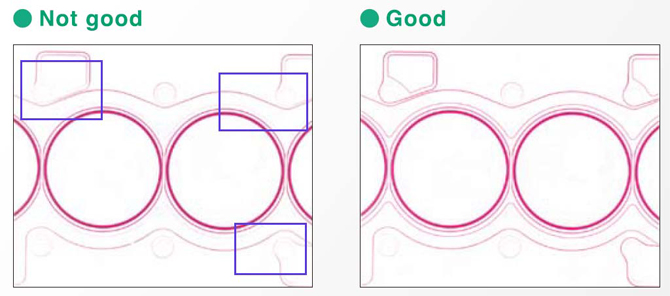

Below is a photo of a developed Fuji Prescale film of a Before and After case of a broken engine head.

The Fuji Prescale developed film clearly discloses the location and extent of the sealing problem: the coolant channels are not properly sealed with the gasket, so coolant fluid will mix with the engine oil. The plastic deformation is located on the inside of the engine head, close to the cylinders where heat is at its highest value. This means that the solution is to grind down the (now) excess peripheral head surface so that the gasket can again establish water-tight joint between the head and body so the coolant can stay within its channels. Thanks to this Fuji Prescale film testing, repair technicians can:

- Cut repair time

- Cut repair expenses

- Localize the defect easily

- Raise repair quality

- Improve repair productivity