Fuji Pressure Measurement Film Helps Hydroelectric Turbines Design Go Green

Keywords: pressure sensitive film, hydroelectric turbine design, mapping tactile pressure, pressure and fish injuries, fuji prescale film Summary: Engineers and environemntalists benefit from the wide range of Fuji Prescale films in designing hydroelectric dams and turbines that are safe for salmon migration. Source: Glen Cada et. a. Use of Pressure-Sensitive Film to Quantify Sources of Injury to Fish, North American Journal of Fisheries Management 25:57-66, 2005

Written by Igor Mateski

How Hydroelectric Turbines Affect Wildlife

In the past several decades wildlife preservation activists have raised the issue of hydro dams and how they affect wildlife, especially fish migration, specifically salmon migration. They have pointed out that dams stop natural migration of salmon downstream, which severely affects their lifecycle.

The problem lies in the salmon downstream migration because the spillover conduits create hydrodynamic that are strong enough to severely wound and even kill salmons. Also, when fish go through turbines and smaller conduits the water flow pushes fish into turbine blades that also results in massive injuries and death of fish.

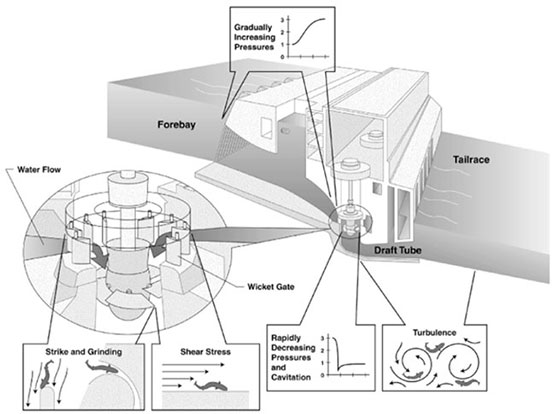

This concern has resulted in numerous studies of how to build hydroelectric dams without them being overly disruptive to wildlife. One recent study has outlined the mechanisms of injuries of fish, presented in the image below:

The journey of a salmon through a hydroelectric facility is divided into three sections, each having a unique set of pressure-related challenges.

The first part of the journey is from the lake through the water ducts into the turbine. Hydrostatic pressure here exerts the strongest load. The second segment is the travel through the actual turbine fan where fish suffer from striking and grinding against the fins or duct walls. Lastly, at the exit of the turbine fish suffer injuries from turbulent flow and cavitation explosions.

Tactile Pressure Mapping Reveals The Problem

To evaluate how water flow (flow amount, flow velocity, number of spillways) affects fish injuries scientists used several Fuji Prescale Film ranges:

- Fuji Prescale LLW for pressures of about 0.5-2.5 MPa,

- Fuji Prescale LW for 2.5-10.0 MPa, and

- Fuji Prescale MW for 10.0-50.0 MPa.

The films were cut into 15.2-cm 3 19.1-cm rectangles (290cm2) and applied to a plastic cylinder that was then placed in a water-proof wrapping in order to eliminate possible pressure readout distortions from water between the films. The three different films were stacked one on top of another, where the LLW wraps the LW, which wraps the MW, which is directly applied onto the plastic cylinder that plays the role of a fish.

To put pressure readouts into perspective, researchers conducted comparison tests with metal and wood balls of various weight, dropped directly onto pressure sensitive films from a height of 10 inches:

"The LLW film is sensitive enough to record slight scratches and small pressures created by the impact of a 0.9-cm-diameter, 2.7-g metal ball dropped from a height of 25 cm.

The LLW film would probably be able to detect and record pressures exerted by jets and turbulent pulses of water... [The] MW film was capable of measuring the impact of a 5- cm-diameter, 535-g steel ball bearing dropped from 25 cm, an impact that would undoubtedly injure fish."

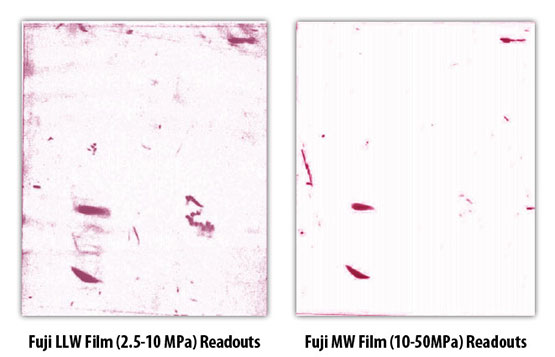

After retrieving the fish sensors, the developed Fuji Prescale Films were digitized for precise analysis:

The tactile pressure maps quickly reveal the size and nature of the injuries. There are very few severe injuries (>10MPa) and cover only 0.08% of the entire surface area, and the lighter injuries although more common, still cover only 1.3% of the surface area of the prescale film.

Fuji Prescale Film Quantifies Progress

Cada et. al. ran this test using 17 sensor fishes equipped with 3 layers of Fuji Tactile Pressure Films. This research was done on the spillways of Bonneville and the Dalles dams in November and August 2002. The samples were sent through the dams using different spillway count and spillway water flow.

After analyzing the digitalized readouts of all 17 sensor fishes and all three grades of pressure sensitive films, the research team assembled several conclusions:

- There were no significant relationships between the volumes of water flowing through the spillbays and the maximum pressure measured by the pressure sensitive film samples

- Pressures were not applied to the entire surface of the pressure sensitive film, but rather reflect relatively small areas of impact. Most films had multiple, small marks; as many as 15 marks were counted. Estimates of the total marked area of the film samples ranged from 0.25 to 3.75 cm2 (0.08-1.3% surface area affected)

- Of the 17 Prescale MW range pressure sensitive film samples, 13 had marks that were caused by impacts of greater than 41.4 MPa... These data indicate that relatively small areas of the surface of the film were exposed to high pressures during passage through spillways, presumably as a result of the sensor fish striking some structure. For these samples, the size of marks was not related to gross characteristics of the spill (number of spill bays and spillbay flow).

Food manufacturing experiments have shown that the salmon muscle fibers begin to break at loads of about 48MPa. Compared to the maximum loads recorded with the Fui Prescale MW range films that measured up to 50MPa loads, it may be indicative that salmon suffer serious injuries when passing through spillways.

But researchers did raise the point that real fish are flexible and deformable, so these impact injuries that measured over 40MPa on small surface areas would in fact be distributed to a larger surface area on real fish, and effectively reduce the tactile pressure loads and prevent muscle tissue damage. Also, live fish may, by swimming, avoid impacts in the spillway.

Thanks to studies like these, turbine engineers, dam engineers and environmentalists can work together to create a better cohabitation of people's need for energy and our desire to preserve our environment.