Diagnosing and Repair of Injection Mold Machines using Fuji Prescale Films

Written by Igor MateskiKeywords: injection mold design, mold manufacturing, repairing of injection mold, diagnosing injection molds to increase mold quality

Summary: Injection mold design and manufacturing revolves around mold components perfect alignment and surface pressure. Faults in mold manufacturing as well as wear and tear cause surface imperfections that result in poor molded products quality and shorter mold life. Fuji Prescale films enable repair technicians to precisely diagnose and repair mold tools and increase production efficiency.

Case 1: Verifying Tactile Pressure Between Moving and Fixed Injection Mold Plates

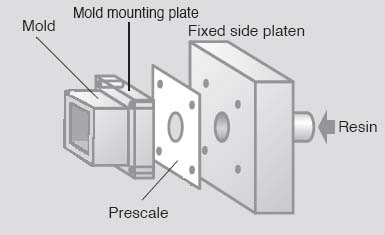

Injection mold machinery is an assembly of at least several parts: the mold positive, mold negative and injection plate. If the manufactured plastic product is complex, there may be more mold parts that must align properly as well as having uniform tactile pressure on every contacting surface.

This requires high precision machining and very fine surface finishing. Ideal pressure distribution on all contacting surfaces means high quality of the mold as a manufacturing equipment that will have longer production life.

There are cases when, for example, the contacting surfaces between the movable mold and fixed side platen do not have the desired ideal pressure distribution throughout the contacting surface.

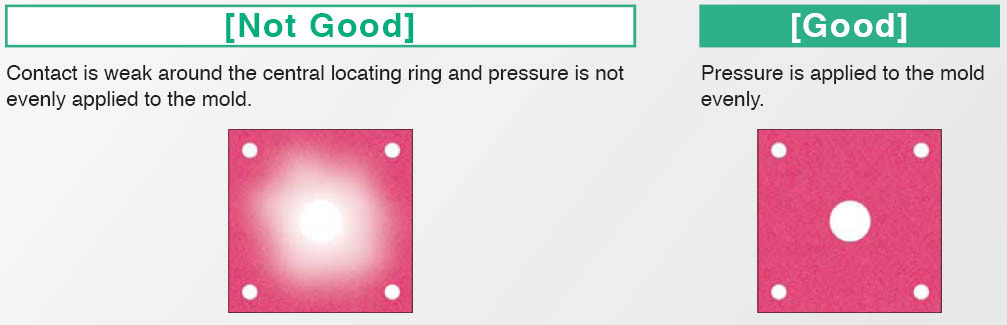

The image above illustrates such a case, where the fixed side platen and mold mounting plate should have uniform tactile pressure throughout the contacting surface.

Manufacturers of molding machines should use the Fuji Prescale film to make sure that what the construction department has designed is now manufactured properly.

Below is a developed Fui Prescale film from a poorly distributed tactile pressure between the two surfaces (image on the left).

Timely diagnosis of this problem is crucial for the longevity of the tool, and the quality of molded products it makes. With proper machining intervention, this defective contacting surface can be repaired and after the repair the developed Fuji Prescale film should show even tactile pressure throughout the contacting surface, as is shown on the detail on the right.

Case 2: Verifying Pressure Distribution Between Moving Injection Mold Plates

Complex molds can consist of many mold plates and the even distribution of contact pressure on all contacting surfaces is crucial to the needed high quality of molded products so that there are no additional production steps eg. removing excess resin where a continuous/flat surface was expected. But wear and tear do happen, and what used to be a perfect molding tool can in time deteriorate.

For this reason, it is important for maintenance technicians to regularly perform tactile pressure screening on all contacting surfaces to make sure that the molded products are of consistent quality.

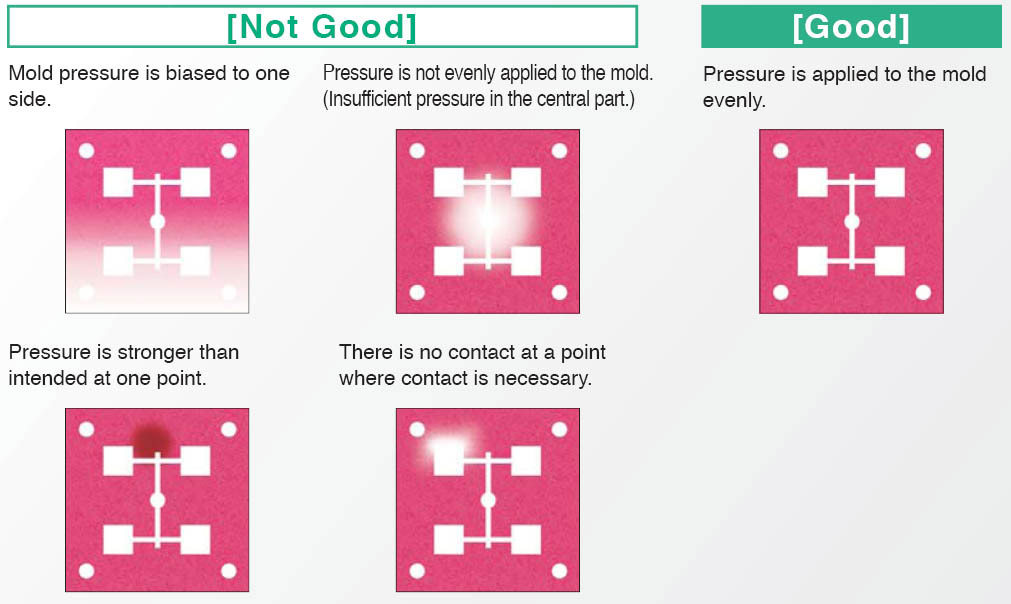

Below are real-life scenarios of how developed Fuji Prescale films reveal tactile defects.

The image above shows several scenarios of the same mold machine with different tactile pressure issues. In all four cases, the uneven pressure distribution will cause either prodution imperfections or excess surface tear which adversely affects the tool's longevity.

Using the Fuji Prescale film, repair technicians can accurately pinpoint and fix the problem so as to get a perfect tactile pressure distribution on the entire contacting surface, as shown in the top image on the right.

Benefits of Using Fuji Prescale in Machining and Injection Mold Production

The Fuji Prescale film is an invaluable tool for maintenance technicians and manufacturing engineers alike. Thanks to smart utilization of the Fuji Prescale, the manufacturing of molded products can reach a high production volume without sacrificing quality. In fact, regularly using the Fuji Prescale as part of scheduled maintenance is the only fast, efficient and cheap way to ensure tools longevity and high production quantity and quality.