Design and Servicing of Pneumatic Sealing Machines Using Fuji Prescale

Keywords: Sealing head defects, sealing head calibration, tactile pressure measurement, thermal sealing head defects Summary: Sealing machines should ensure fast and reliable sealing for long periods of time in continuous use. To avoid surface ware and tear, while keeping a high life-time and low production cost, sealing machine manufacturers and servicers rely on Fuji Prescale films to ensure proper alignment and surface pressure.

Written by Igor Mateski

Requirements From a Pneumatic Sealing Machine

Pneumatic sealing machines are ubiquitous in many industries:

- food packaging

- medical materials manufacturing

- pharmaceutical industry

- chemical manufacturing plants

- cosmetics factories

Such requirements translate into technical requirements that a sealing machine needs to meet. This means that the sealing components must be made from a material that will not be susceptible to ware and tare, that will have solid thermal conductivity and good mechanical strength that must be unaffected by the heating and cooling cycles during normal operation of the sealing machine.

Using Fuji Prescale To Eliminate Problems in Sealing Machines

Research teams have spent plenty of time experimenting with materials for the sealing heads and in their work design engineers rely on Fuji Prescale to test the surface pressure exerted by the sealing head.

The primary cause of sealing quality deterioration is surface ware and tear of the sealing head, partly due to thermal cycles, and partly due to tactile pressure variations. When the tactile surface of the sealing head deteriorates, sealed joints may suffer from thermal over-exposure, or insufficient thermal exposure that results in poor sealing that will not be able to provide proper air-tight containment of the packaged goods.

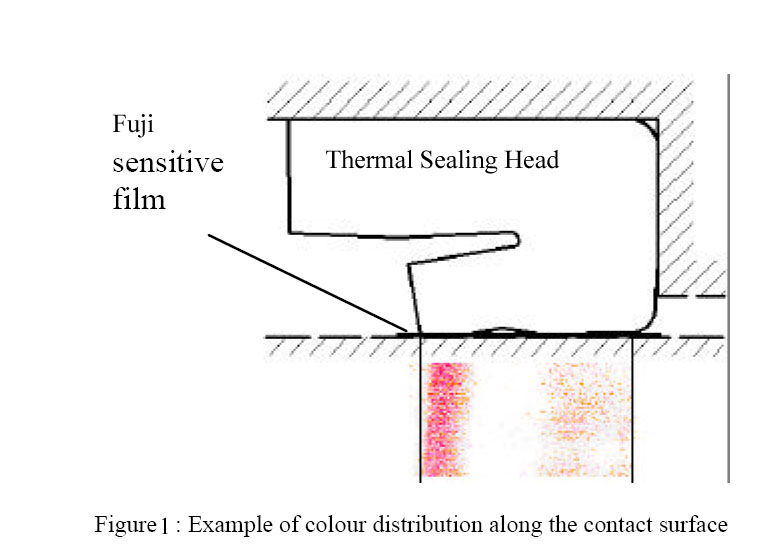

Below is a schematic view of how engineers and repair technicians use Fuji Prescale to test for tactile pressure distribution as means to evaluate the sealing heads condition.

The example above shows a tactile pressure inconsistency that can result in poor sealing action. This defect can result in inconsistent sealing and entire batches of finished products may be lost or shipped before the defect is located.

Thanks to Fuji Prescale, technicians can quickly test for tactile pressure inconsistencies and replace the defective sealing head and run calibration tests without using production materials and do retrospective analysis.