Contact Pressure Mapping for Particle Accelerator Power Switches

Written by Igor Mateski

Keywords: tactile pressure mapping, pressure distribution in electric contact surfaces, pressure symmetry mapping, pressure balance mapping, fuji prescale film, high voltage switches design

Summary: Designing high voltage power switches requires strong tactile pressure and solid pressure symmetry. Using the Fuji Prescale Film engineers can quickly evaluate and fine-tune tactile pressure thanks to direct pressure mapping readouts.

Requirements for Particle Accelerator Power Switches

Particle accelerators work on high voltage, high amperage currents and require fast circuit breaking ability, as well as guaranteed long operation lifetime. With up to 2.2kV current, and up to 2.5kA power, these switches need a reaction time of 20kHz.

Since the voltage and amperage values are quite high, switches require high contact pressure (30kN) evenly distributed across the electrode faces to ensure proper and safe breaking of electricity.

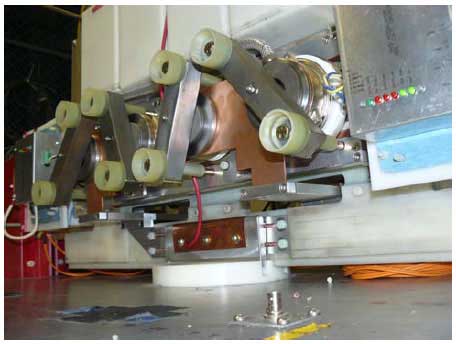

Below is an image of a press-pack switch plate for use in particle accelerators:

Tactile Pressure Mapping with FEA

Mechanical devices that operate on such a high frequency must be perfectly balanced so that each of the switching surfaces gets the same tactile pressure to perform its function properly.

Press-pack switch plates usually tend to have solid characteristics thanks to precise manufacturing that starts with FEA models.

When modeling the contact plates, the FEA modeling takes into consideration the needed breaking speed (in order to avoid arching) and contacting force. Depending on voltage and amperage, this force is distributed along all contact plates where the tactile pressure must be balanced so that the breaking action is done simultaneously throughout.

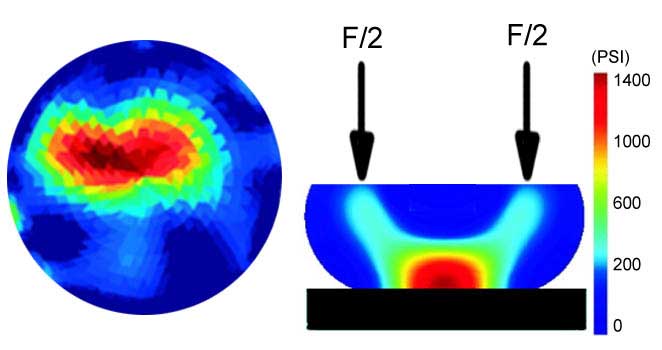

The image below shows a FEA tactile pressure readout of a contact pair loaded with a nominal force of 30kN. The construction of the contact filament uses two points of force load in order to offer a more balanced load distribution.

In FEA models, pressure distribution shows good tactile pressure distribution. However, engineers need to resort to lab-testing a prototype switch board to verify pressure distribution as well as pressure map symmetry.

Using Fuji Prescale to Map Tactile Pressure

Direct pressure mapping between two surfaces is an excellent verification method that the FEA model and manufacturing techniques result in a prototype that is ready for manufacturing.

The easiest way to measure tactile pressure between two surfaces is to use the Fuji Prescale film that matches the nominal loading force. Fuji Prescale LW tactile pressure films match the loading pressure (1400PSI).

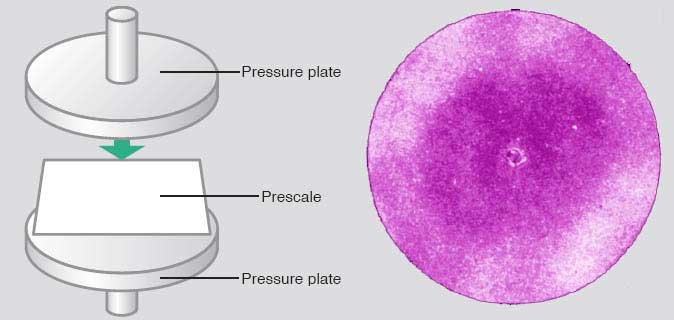

Below is a developed Fuji Prescale LW film that reveals the tactile pressure map between two contacting surfaces:

To get a direct pressure readout, technicians can cut the Fuji Prescale to size, and place the film between the two contacting plates where pressure mapping is required. When the Fuji Prescale film is in place, the two plates are loaded with the nominal pressure that develops the pressure sensing film.

The film can be directly evaluated for:

- pressure balance,

- pressure distribution and in this case,

- pressure symmetry.

Thanks to this direct pressure mapping approach, technicians can quickly and easily visualize tactile pressure and make needed adjustments. This developed prescale film can also be scanned for further precise digital analysis using the FDP 8010E pressure mapping system.

Related Case Studies for Lamination Pressure and Roller Defects :

FPD-8010E Pressure Digitalization and Mapping SystemUsing Fuji Prescale as Quality Assurance in Fuel Cell Manufacturing

Visualization and Measuring Tactile Pressure using Fuji Prescale and FDP 8010 Digital System