Checking water-tight joints using Fuji Prescale Film

Written by Igor Mateski Keywords:Pressure distribution measurement, Quality Control of water-resistant devices, assembly alignment measurement Summary:Devices that need water-tight joints rely on precise assembly and perfect alignment. Deviations in the manufacturing and assembly process can cause pressure dis-balance and variations of the water-tightness of the joints. Fuji Prescale Films can help discover pressure discrepancies and improve the quality of water-tight products.Water-tight devices and the need of water-tight joints

The electronic industry has penetrated our lives thoroughly, and people are not willing to part their wrist watch and nowadays even their cell phone while in water. This puts an extra strain on engineering teams in building light-weight yet completely water-proof electronic devices:

- Water resistant watches

- Water resistant cell phones

- Water resistant cameras etc.

The growing demand of water-tight gadgets allows manufacturers to offer added value to their devices by making them water tight. Yet it is the R&D teams that need to solve the challenge of making an electronic device water-friendly.

Water-tight joints of serviceable devices relies on establishing strong enough contact pressure between the chassis components of the device. This is why the importance of getting an even pressure distribution along all joints is paramount. If the joint surfaces are loaded with stronger pressure at some joint points, and there is lower pressure on other joint points, the water-tightness of the chassis is compromised.

If we add in the effect of vibrations on water-tightness in military-grade devices, the problem of establishing water-tight assembly escalates further. Military-grade water-tight devices are subject to unusually strong vibration, dust and pressure loads; yet the water-tightness of joints must not be compromised.

Solving the Pressure-Problem with Fuji Prescale Films

When we factor in all these elements:

- Vibrations

- External loads

- Water-resistance to certain depths

- Thermal stability of joints

it is obvious that keeping the same amount of pressure along the length of the joints becomes a real problem.

Also, other manufacturing and assembly technical issues can cause even more problems:

- Plastic chassis molds suffer minute warping during the cooling process and the surface is not ideally flat

- Cold-pressed metal housing does not get the ideal shape due to metal elasticity

- Ceramic housing elements deviate from specified dimensions due to manufacturing imprecision

The external loads and manufacturing issues combined, create a complex problem that R&D teams need to deal with, on a budget, and on schedule.

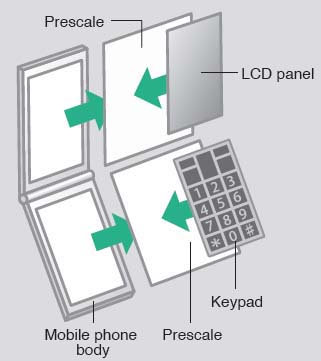

Below is a schematic overview of how using the Fuji Prescale Film can help R&D teams and engineers to test the chassis alignment with the water-proofed LCD panel and Keypad.

This test can help engineers see any pressure discrepancies that can lead to no, or reduced water resistance of their prototype cell phone.

If the cell phone is graded to be water resistant for depth of eg. 10 meters, the contacting surface size and pressure are already predefined and the engineers only need to see if the assembly provides the needed contacting footprint and pressure.

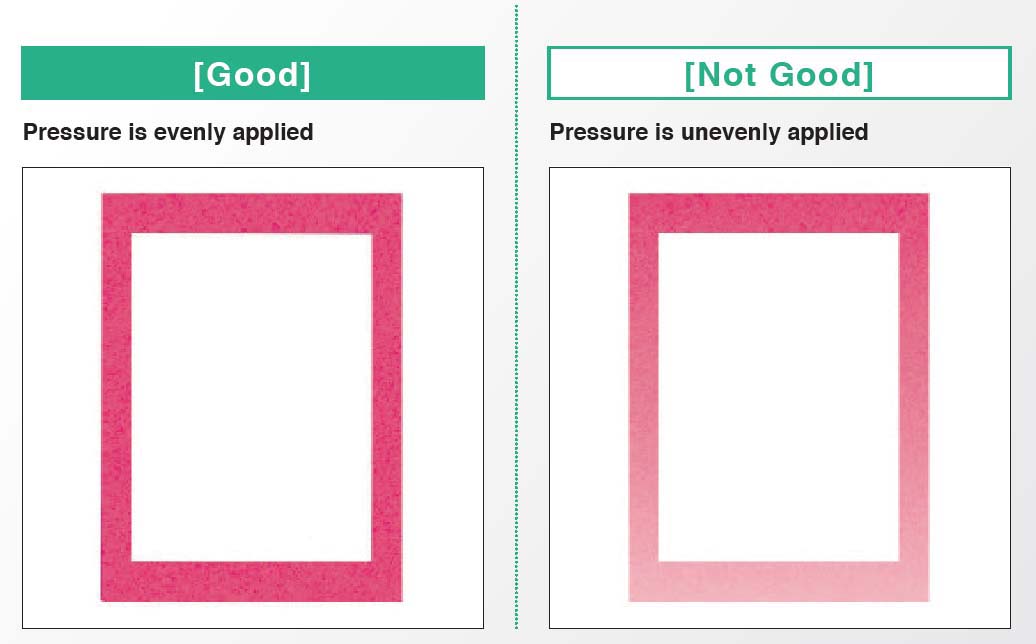

The image above gives a sealing surface that is well-formed (left image), vs. the poorly formed sealing surface on the upper right image.

This uneven contacting surface pressure can lead to compromised water-resistance to the specified depth, or in some units can cause total loss of water-resistance.

Benefits of Using the Fuji Prescale Film in R&D of Water-tight Devices

The pressure on R&D teams and engineers to launch new products with higher and higher performances is tremendous.

The market is quite demanding and unforgiving to companies that market their products as water-tight, yet fail to make each produced unit as water-tight.

Fuji Prescale Films can greatly help you and your colleagues in the development and optimization of your design so that you can:

- Cut time and development costs of new product designs

- Eliminate production and assembly flaws

- Ensure water-tightness of every produced unit

So don't hesitate to contact us for more information or even a free sample of the Fuji Prescale Film.