Pressure Distribution on a Lamination Press: Fuji Prescale as Diagnostics Tool

Keywords: paper manufacturing, roller alignment, roller pressure balance, fuji prescale alignment, fuji prescale balance Summary: Servicing paper production roller-based machines is an expensive process. Using the Fuji Prescale LW and LLW films the servicing period and cost get significantly lowered, while the productivity and quality of the end products get improved. Written by Igor MateskiRoller Pressure Balance and Alignment as a Production Variable

The paper industry is dependent on precision machinery to produce paper rolls as raw production material, as well as producing final paper products like printed materials, perforated paper etc. All of these production processes use roller-based machines to format, print and perforate paper.

As roller-based machines are almost fully automated, they operate 24/7 for months on end. During this time, ware and tare appear and the factory-set alignment and roller pressure balance slowly deteriorate. This pressure balance and roller alignment deterioration result in decreased quality of the final product, as well as decreased productivity due to paper drift and uneven formatting/printing/perforation.

Servicing Paper Roller Machines without Fuji Prescale

Servicing roller-based paper machines usually means exchanging the rollers and using a test batch of paper to see:

- The rollers pressure balance along the entire length of the rollers

- The rollers alignment with each other

This kind of servicing usually comes out with two outcomes:

- The rollers are properly aligned and balanced, so production resumes

- The rollers are not aligned and balanced, the test paper batch is wasted, and the rollers are returned to the manufacturer with a replacement request. In the meantime the old rollers are placed back so production can continue

This kind of servicing is not optimal on several levels

- Material loss: Each time a new roller set is installed, hundreds of meters of paper can be wasted on testing.

- Production loss: For a new roller set to be installed, production needs to be halted. Depending on the size and complexity of the machine, the servicing time can last for days. During this time, the factory is out of production which has direct dollar loss for the company.

- No established diagnosis: Not knowing the root cause of loss of the alignment or pressure balance means that several sets of rollers can be discarded, while the reason of misalignment or pressure dis-balance can actually be caused by a different factor like the machine's subtle displacement from its perfectly horizontal position, or other mechanisms misalignment.

Fuji Prescale Films: How and Why use it in Servicing of Paper Roller Machies

The ideal servicing procedure of roller-based machines is to use the Fuji Prescale LW (low pressure) and LLW (super-low pressure) grade pressure sensitive film to test the roller pressure balance and alignment of the newly installed rollers.

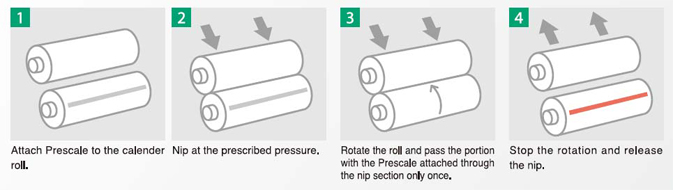

The image above gives a short and practical advice of how to do the roller pressure and alignment testing of the new rollers. The key here is to align the Fuji Prescale film properly, and to make a single rotation so that the developed film displays the pressure/alignment profile of the circumference of the rollers.

Below is an image of how a developed Fuji Prescale film looks like on a machine with:

- Poor pressure balance along the length of the rollers

- Poor alignment of the roller couple

- Poor pressure balance and misalignment of rollers

- Properly balanced and aligned rollers

The first developed Fuji Prescale film clearly reveals a poor pressure balance problem. The center section of the rollers exerts more pressure on the paper which will result in poor production and increased ware and tare of the rollers surface. In this case, the rollers need replacement.

The second developed Fuji Prescale film is from a misaligned roller couple where the two ends of the roller axis are not in the same vertical plane. In this case the rollers are pressure balanced, and the repair technician only needs to properly align the roller axis.

The third developed Fuji Prescale film reveals both an alignment problem, and a pressure balance problem. In this case, the rollers need to be replaced because the pressure balance reveals bulging in the mid-section, and the rollers will need to be aligned properly so that the axis of the rollers lay on the same vertical plane (assuming the rollers are stacked vertically).

The fourth developed Fuji Prescale film is from a roller stack that is properly aligned, and the pressure balance is even along the entire contacting length.

Benefits of Using the Fuji Prescale LW and LLW

With Fuji Prescale LW and LLW (low pressure and super-low pressure respectively), the servicing process of roller-based paper machines:

- Saves time: technicians can quickly establish a proper diagnosis and effectively eliminate the defect

- Increases production quality: the paper rollers will enable even travel and pressure of the paper so the printed/perforated end product will show no signs of drift or pressure dis-balance

- Improves the lifetime of rollers: with Fuji Prescale, technicians can discover any pressure dis-balance and make the necessary interventions so that the contacting surface of the softer roller will not get damaged

Thanks to the Fuji Prescale films, your team can more effectively service the roller based machines, so that your company can optimally use the production resources to manufacture high quality products without sacrificing productivity