Fuji Prescale 4LW Helps Map Lamination Tactile Pressure Range in Manufacturing Microfluidic Structures

Written by Igor Mateski

Keywords: Fuji Prescale 4LW, lamination, thin film resist, tactile pressure range, direct lamination pressure mapping, microfluidic structure manufacturing

Summary: Instrument-on-a-chip biomedical devices use microfluidic structures that need to ensure proper fluid flow. These laminated structures require exact lamination tactile pressure with very small variances. Using the Fuji Prescale 4LW film, manufacturers can cheaply, easily and quickly measure the lamination tactile pressure and ensure proper lamination of microfluidic structures.

Importance of Microfluidic Structures

Medical devices are growing smaller and smaller thanks to integrated design. Instrument-on-a-chip medical devices pack a large list of capabilities that make our lives better. From digital blood sugar meters to implants, these devices use microfluidic structures in order to minimize dimensions and increase precision at the same time.

In more complex instruments, these microfluidic structures need to cope with various manufacturing requirements such as resistance to various chemicals, thermo-stable channels, durability etc. In many cases, the fluid flow requirements mean opting for a multi-layered, laminate structures. Given the extremely small dimensions and low tolerances, manufacturing of these microfluidic structures becomes a challenging process.

Role of Tactile Pressure in Microfluidic Manufacturing

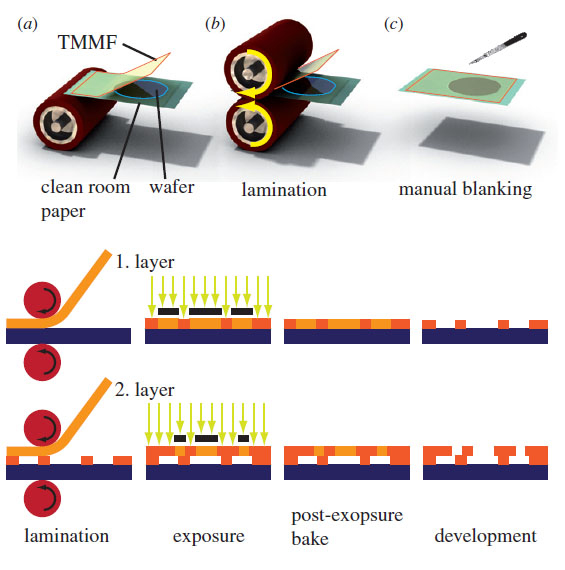

Microfluidic structures manufacturing regularly uses lamination, photo-lithographic and thermal processes. As channel (piping) dimensions grow smaller, so grows the technical challenge of establishing a reliable, fast and affordable lamination manufacturing process. Below is a simplified lamination manufacturing process used to make a multi-layered microfluidic structure:

Lamination Manufacturing of Microfluidic Structures

The image above shows how the manufacturing process uses lamination, photo-lithography and temperature to produce the needed multi-layered structure. With smallr dimensions of these channels, it difficult to balance the tactile lamination pressure that ensures proper sealing between layers, while ensuring that no channels get clogged during the exposure and baking phases of manufacturing.

Using Fuji Prescale LLW to Define Tactile Pressure Range

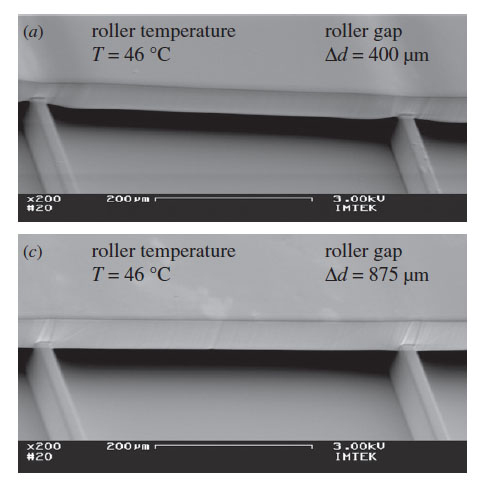

Various researches recommend a 5:1 or even 7: 1 Width-Height ratio where the adhesives used and baking temperature create various challenges. However, the lamination process also relies on thermal bonding in which case the laminating tactile pressure plays a crucial role in achieving proper layer adhesion without the risk of channel clogging. Below is an actual photo of the role of laminating tactile pressure on proper forming of the microfluidic structure:

How lamination tactile pressure affects channel geometry

The image represents two cases of lamination performed under different tactile pressure. In the image above the pressure is represented with the distance between the two thermo-laminating rollers (see image 1). These rubber rollers exert pressure that can be changed by altering the axial distance between the rollers.

If the tactile laminating pressure is too low, there will be poor thermal bonding of the two layers which will result in unwanted leakage. If the tactile laminating pressure is too high then channel geometry can change and alter the fluid flow, or they can even get completely clogged.

This problem intensifies in high-yield manufacturing where these rubber rollers are susceptible to ware and tear, and dimension tolerances are in the range of a few micro-meters.

To ensure high yield and high quality, manufacturers must regularly measure the tactile pressure between the rollers, manufacturers use the Fuji Prescale 4LW films which are charecterized with high mapping resolution and low activation pressure.

Thanks to the Fuji Prescale 4LW film, manufacturers of microfluidic structures can quickly, cheaply and easily measure the laminating tactile pressure that is needed to ensure proper lamination and avoid channel clogging.

Related Case Studies for Lamination Pressure and Roller Defects :

Using Fuji Prescale To Check Surface Defects of Paper Size Rubber RollersPressure Distribution on a Lamination Press: Fuji Prescale as Diagnostics Tool

Diagnostics and Repair of Expensive Office Printers With Fuji Prescale Films