Designing Environmentally Friendly Refrigeration Units With Fuji Prescale

Keywords: gasket deformation curve, gasket design, refrigeration compressor design, sealing properties, increased nominal pressure, verifying FEA tactile pressure with fuji prescale Summary: Environmentally friendly refrigeration units use fluids that operate on higher nominal pressure. This requires compressor design alterations and gasket design improvements to ensure sealing throughout the unit lifecycle. Fuji Prescale helps verify FEA models in pre-production phase.

Written by Igor Mateski

The Refrigerant Issue After Kyoto

The Kyoto agreement requires that manufacturers abandon using of refrigerant fluids that have contributed to the global warming problem. These new refrigerants that are environmentally friendly usually work under higher nominal pressures. This increase in nominal pressure pushed manufacturers of refrigeration equipment to undergo massive redesigns on their compressor units, particularly the gasket joints that must ensure proper sealing throughout the lifecycle of the unit.

Challenges of Rapid Gasket Joint Design

The Kyoto effects on the refrigeration industry at its core is economical. Manufacturers must quickly adapt to new refrigerants and as there is a constant improvement in the fluids themselves, refrigeration compressors must follow. This calls for rapid gasket joint design in order for manufacturers to stay competitive.

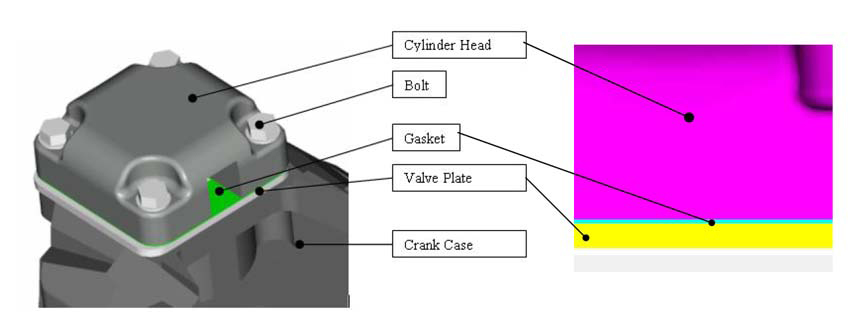

For the sake of competitiveness, CAD/CAM is a household process where engineers heavily rely onn FEA to establish working models of compressors. However, the critical head-gasket-case assembly is even more critical as nominal suction and discharge pressures increase for the modern refrigerant fluids. FEA models can only go as far as rapidly developing a prototype that only serves as a testing model and cannot be used for large-scale manufacturing.

The problem with FEA models is that there are a lot of simplifications in the model and elements, especially the gasket. However, gaskets are the only element in the gasket joint that has significant and complex planar and axial deformations which cannot be precisely factored in the FEA model and this results in unreliable pressure computations that must be verified on the prototype model.

Combining FEA and Fuji Prescale

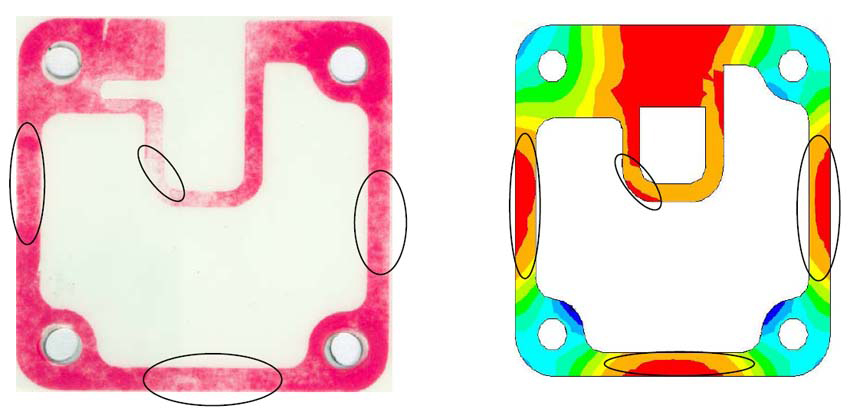

Recent studies show that a FEA model, although simplified, can give approximate tactile pressure values to experimental, Fuji Prescale pressure readouts.

One such study was presented at the International Compressor Engineering Conference at Purdue, July 17-20, 2006. The study showcased a well-balanced FEA approximation of the tactile pressure on the gasket joint that was later verified using a Fuji Prescale film.

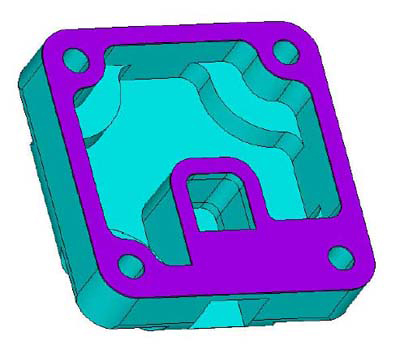

Engineers first modeled a FEA model and using the ANSYS system applied nominal bolting pressure.

The model was geometrically simplified and the gasket was set as a homogenous material that only has thickness deformations in order to decrease computation as well as modeling time. Tactile pressure is calculated based on nominal bolt tightening force.

Using this simplified model, the computed tactile pressure map was compared to a Fuji Prescale developed film using real-life prototype built based on the FEA model. The nominal bolt tightening force was identical to the computed model.

Below are images of the 3D mesh model of the head, the tactile pressure distribution and the developed Fuji Prescale film.

The image above is a side by side comparison of the ANSYS tactile pressure readout and a developed Fuji Prescale film. The marked out low-pressure regions are found both in the ANSYS model and on the Fuji Prescale film.

Thanks to the confirmed pressure readouts from this Fuji Prescale film, the FEA model can be refined so these low pressure regions can be avoided. Engineers can opt for either using a harder material, more bolts or a better gasket design that will provide reliable sealing at the nominal pressure for this new, environmentally friendly refrigerant.